Pizza Production Line High-Capacity Pizza Dough Former

Dough Hopper

The mixed dough is poured into the feeding hopper of the machine through an elevator. The feeding weight is tailored to match the production capacity of the line, ensuring smooth and continuous processing without delays.

Dough Forming

The dough belt forming system uses a low-stress processing method to gently shape the dough into the required width and thickness. This careful handling preserves the dough’s structure and keeps it soft.

Dough Resting and Cooling System

The dough belt is transported to a low-temperature relaxation tunnel, which allows the dough to rest as needed. The tunnel is equipped with an anti-condensation device to prevent the dough from drying out or cracking, ensuring perfect consistency.

Satellite Rolling

The satellite wheel type dough rolling tower gently handles the dough belt, spreading grease evenly and rolling the dough to the preset width and thickness. This dough belt then moves on to the dough belt forming system, also known as the bread shaping system.

Gauging Roller

The gauging roller sets the final width and thickness of the dough belt after multiple rolling passes. This step ensures the dough meets the specific production capacity requirements.

Flour Sweeping

- Two bottom sweepers

- One top sweeper

- Manual adjustment of operation height

- Manual adjustment of operation angle

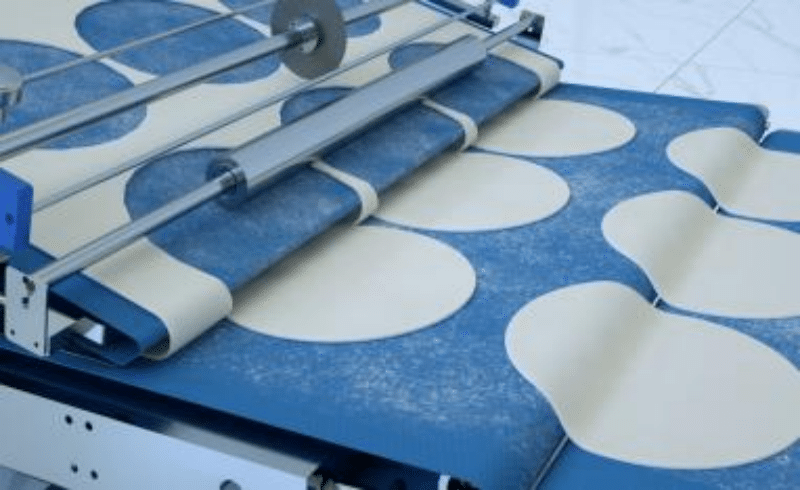

Moving Heel Cutting

After sheeting, when the dough belt reaches the dough forming section, it is cut with heel cutting to ensure perfectly round pizzas.

Residual Recovery

The shaped pizzas are transported to the next belt, while the residual dough is recycled and reused through the recycling belt.

Filling Depositor

The shaped pizzas are then transported to the filling depositor, where tomato sauce is poured onto their surfaces.

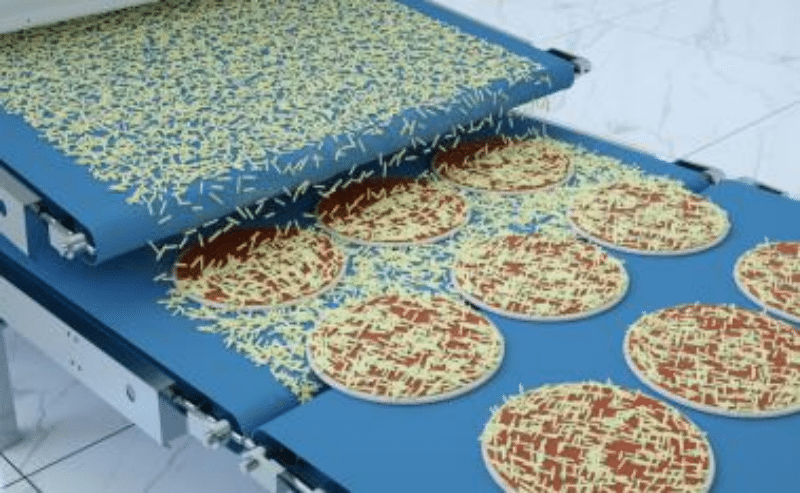

Filling Cheese and Vegetables

Finally, cheese and vegetable mixtures are poured onto the pizzas via a belt system. Any residual filling is recovered and conveyed to the next step.