Create the perfect croissant automatic production line

The ZL1168 Croissant production line is the optimal choice for industrialized production due to its precise design, which ensures uniform shape and consistent tightness of the croissants. Additionally, it can accommodate various fillings such as chocolate and jam. The combination of vertical cutting mode and the triangle die prevents sliding during the cutting process.

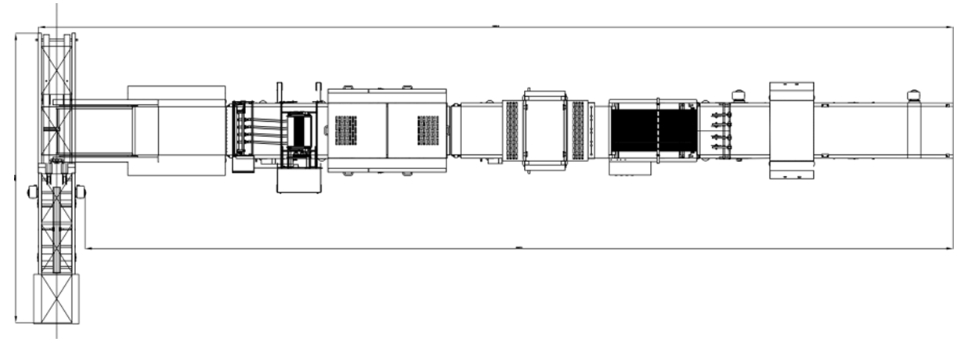

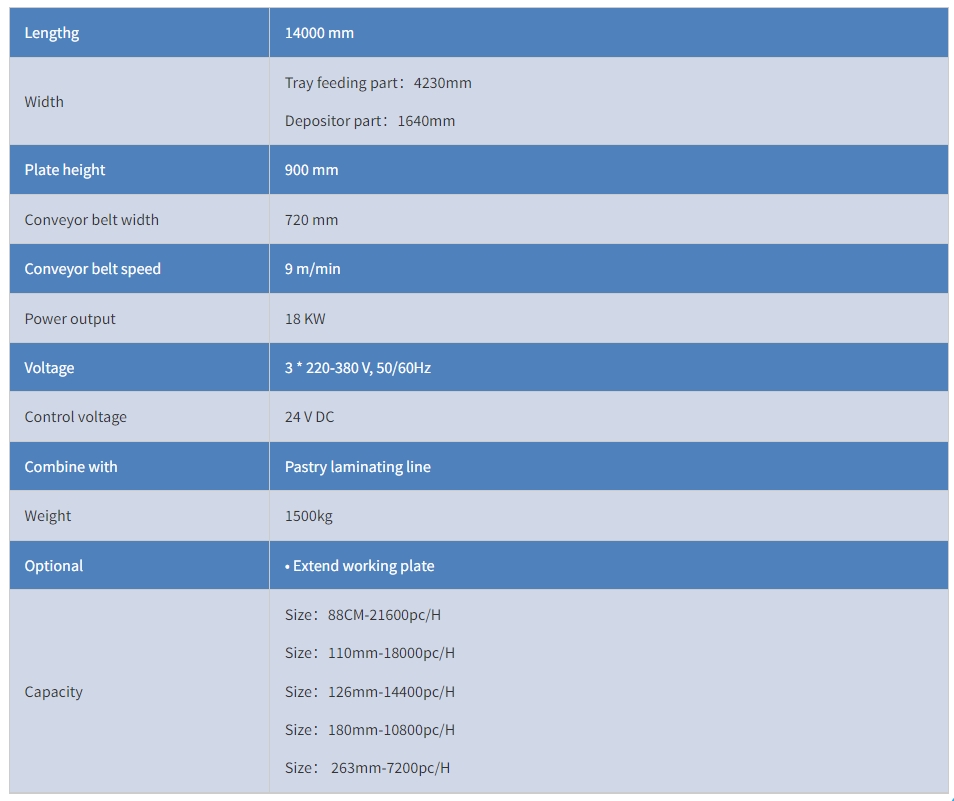

By controlling the conveyor belt intermittent operation device, each row of triangular dough is neatly separated, while the steering device rotates the passing dough 90 degrees to ensure that all triangular dough enters the roll-wrapper in a centered and unified position. Furthermore, the rolling device can be adjusted to control the tightness of the roll as needed. With a compact structure and a total length of 14 meters, this croissant production line offers efficient and precise performance.

Details

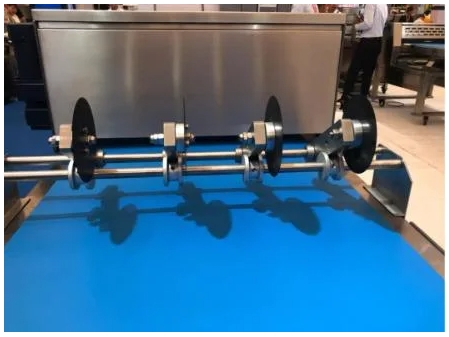

Satellite roller group face pressing device (width limiting rolling surface 480mm)

—Press roller

—Adjustable speed

—480mm Wheel width 480mm

—480mm With the effective width of 480mm

—304,242mm . 304 quality stainless steel roller, diameter 242mm .

—The thickness of the face can be adjusted and readable by hand wheel .

—6:1.8 rotation of the wheel group, the maximum thinning ratio 6:1 .

—3-50 mm Roller can be separated from 350mm

—418 mm Satellite roller unit diameter 418mm

—74 mm Satellite of small drum:74mm

—242 mm Lower roller diameter242mm

— The thickness of the face can be adjusted and readable by hand wheel

—SEW . SEW integrated machine for motor and reducer

Sweeping

— Electromechanical drive

—SEW integrated machine for motor and reducer

— 304 SUS304 Stainless steel whole machine

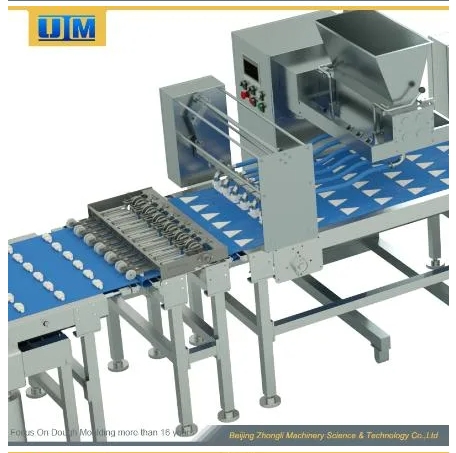

Double-tool cutter holder cut into strips or flowers

—Two tool holder brackets

—Strong handles facilitate tool pressure adjustment

—The gear device ensures that the pressure is uniform at each time, and the pressure-resisting drum under the cutter base ensures accurate cutting.

—The diameter of the axle rod of the cutter tool is 30mm, and it will not bend even under great pressure, so as to ensure that the cutting force is uniform.

—Dongyuan Electric Machine

— 304 high quality stainless steel blade plated

Spreading belt

- Food grade PU Material – Adjustable position

- Sew Electric Machine and Reducer 304 high quality stainless steel

Shaping cutter

—Electromechanical drive

— Fastest speed:150 times per minute

— The shaping cutter is directly stored in the mold after cutting

—304 high quality stainless steel blade outside of PTFE

—SEW integrated machine for motor and reducer

— Miki brake clutch

Electromechanical drive

— Fastest speed: times per minute

— The shaping cutter is directly stored in the mold after cutting

—SEW integrated machine for motor and reducer

— Miki brake clutch