Egg tart forming machine line

Product Detail

The whole line is designed to create flexibility, quick product change-over, easy operation and cleaning. Products can be

made in different foils, paper containers, metal baking trays, hoops, tins as well as indented baking trays. For example:

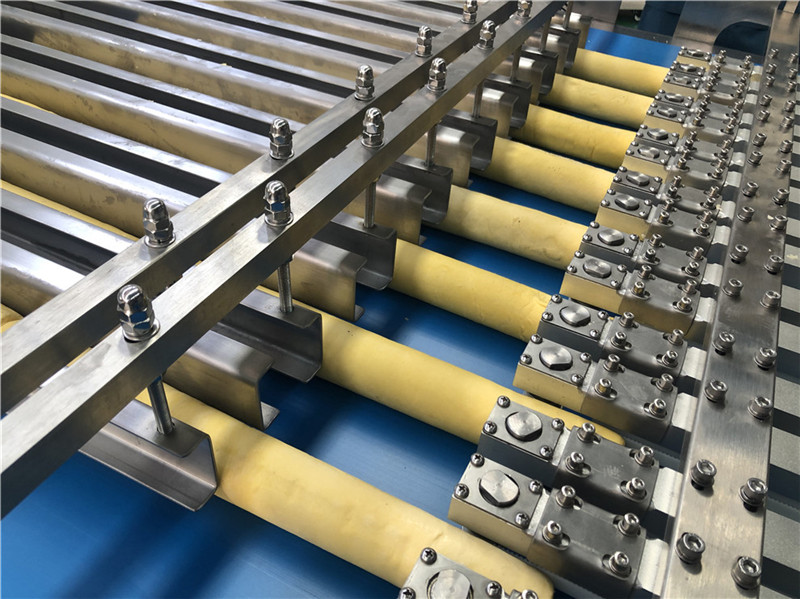

• The blocking and crimping heads are exchangeable at operator side by one person (4 & 8).

• The space underneath the conveyor in general is 250,500,800 mm, which enables good access for cleaning.

• Relevant units are wheelable (4.6.8).

• The heating method of the Punching adopated water heating. The heating temperature is between 48-52 ℃ ± 1 which according to the moisture of the pastry dough.

• The line can be equipped with different feeders depending on different Pastry roller diameter .

• After demoulding, Egg tart billet can be arrange on a tray or directly convey frozen automatically

Capacity

•The capacity of the pie line varies per size,

•Diameter 40 mm up to 20.000 pieces / hour

•Diameter 260 mm up to 5.200 pieces / hour

•Length of the line starting at 10.5 meters

•Product diameter 40 to 260 mm

•Working width 600 – 1200 mm

•Working height 850 mm

Product Specification

| Machine size(L*W) | 18(L)*2(W)*1.85(H) |

| Working height | 850mm |

| Working width | 600-1200mm |

| Product diameter range | 40-260mm |

| Row | 4-6-8 |

Machine details show

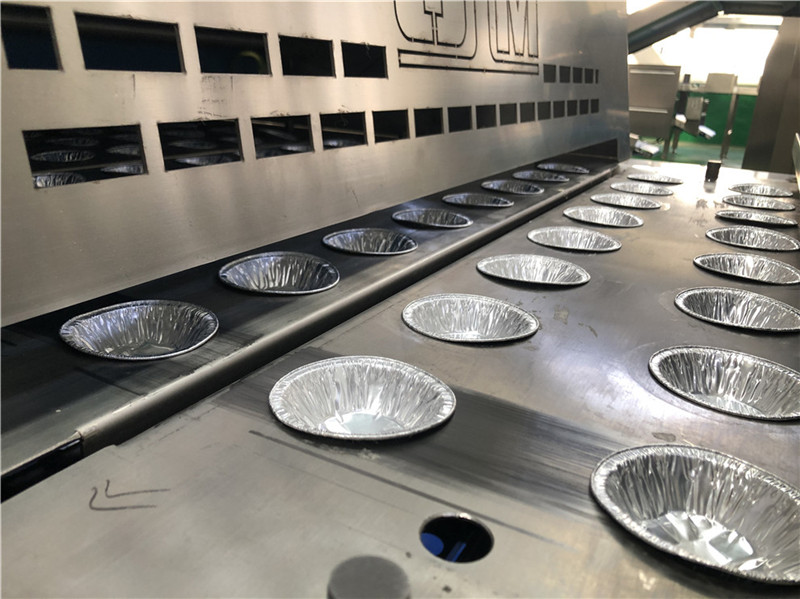

The foil denester is provided with a vacuum system to ensure that the foil is correctly placed.

Dough processing: the UIM Strip feeder

The guillotine ensure very accurate dough weight. and Precise product drop position

The dough billets are blocked to the desired shape without any scrap by a servo driven press. The blocking head is water heated for a precise and reliable operation.

The outfeed system transfers the pies from the conveyor towards dedicated panels but can also be delivered with a set-up for offload to oven band, freezer infeed or trays.